Corrugator Machine-Corrugated Cardboard Manufacturing Process

The raw material papers for corrugated cardboard are specific grades called linerboard and corrugating medium or fluting medium. And the linerboard is the surface of corrugated cardboard, and have stronger tear resistance and strength. Corrugating or fluting medium is the paper which is corrugated in the single facer , after corrugating, it have more folding strength and compression strength. Two linerboard and one corrugating medium can make up 3 ply corrugated cardboard with adhesive glued together,which is applied to the tips of corrugated flutes. The adhesive is normally made of starch most common being maize.

Corrugated cardboard with lineboard and corrugating medium

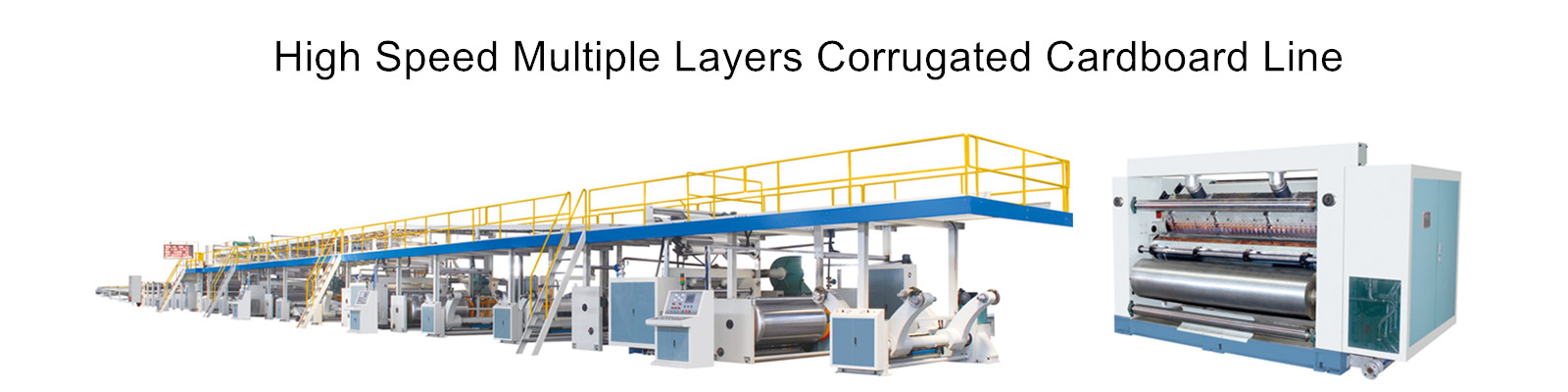

The corrugator machine or called as Corrugated Cardboard Production Line is a set of machines in line, which can bring three, five or seven sheets of paper to form single, double or triple wall cardboard, the corrugated cardboard manufacturing process can be ahieved in continuous process.

The reels of paper are fed into the single facer and is conditioned with heat steam. The corrugating medium get flutes between corrugating rollers in single facer, next step starch is applied to tips of the flutes then inner liner is glued to them, then the corrugated medium and liner are out of single facer together which is called as single face web. Out of single facer, the single face web come into double facer where it meets the outer liner and forms 3 ply corrugated cardboard. After the double facer, it’s through slitter scorer and cutting off machine, stacked at the end.

We have produced a totally advanced Single facer with Two Pairs of Corrugated Rollers in different flutes, which can change the flute without stopping in 15-30 seconds and resume to production in 2-3 minutes.