How Corrugated Paperboard is made in the history

Although a Fourdrinier pape making machine was built in the United States as early as 1827, paperboard

itself was made by hand until George S. Shyrock installed the first cylinder machine in his plant near

Chambersburg, Pennsylvania, in 1831. Shyrock was soon cranking out binders board and boxboard at

the rate of one-fifth tons a day .Paperboard production was executed solely on cylinder machines, like the one below from 1886, until the Fourdrinier endless-belt process was adopted for its production in 1911.

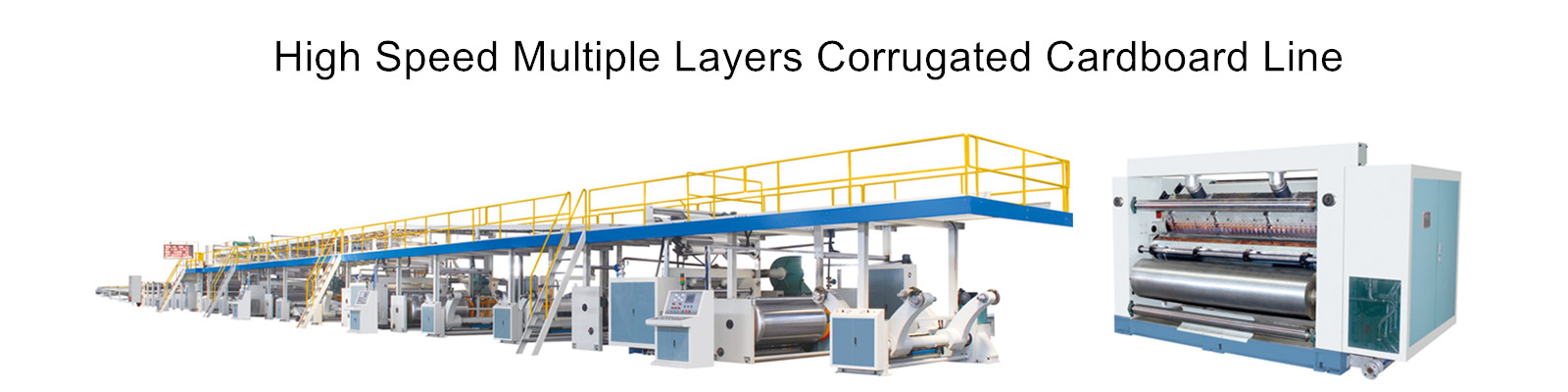

Corrugated Paperboard making line

Manual Methods: The nascent days of the corrugated cardboard industry were exemplified by pioneers who made everything by hand-including their own machinery-and who dreamed of faster methods of production. Beginning in 1838, Colonel Andrew Dennison used this cobbler´s bench in Brunswick, Maine, to manufacture jewelry boxes to complement and protect jewelry and watches sold in his son Aaron’s retail shop in Boston, Massachusetts. Colonel Dennison used a shoe knife and an awl to score whatever stock he could secure.

A Family Affair: At times, when Colonel Dennison longed to spend time away from the cobbler’s bench and spend time with family, he would cut the blanks by hand, holding them on his lap. After cutting the blanks, his daughters, working out of their small home, would finish the boxes. A significant interchange of handwritten correspondence between father and son helped to coordinate the family’s efforts.

The Cutting Edge: In 1884, the father and son combined their efforts to create a device called the “half machine,” which spelled the end of hand cutting of corners. Blanks were cut to size and placed into the machine, which scored and cut one corner at a time with four downward motions. It was known as the Dennison scorer and cutter.

Improving the Cutting Edge: In 1850, a hand shear was developed as an improvement over the cobbler’s knife for cutting box blanks. The shear soon became the main too) in the production of boxes and later would inspire George E. Jenks of Lafayette, Indiana, to name his magazine SHEARS. Before power cutters became numerous, a single box plant might have a battery of as many as eight or ten shears, all operating at once.

Peddling Paper: In 1864, immediately after leaving military service during the Civil War, in which he served on the Union side, Robert Gair started a paper merchant business. At that time, before the introduction of Dennison’s jewelry boxes, the paper business was the packaging business because goods were wrapped in single sheets of paper or put into bags fabricated from heavy brown wrap. At right is his first account book. In a decade’s time, Gair would be the foremost pioneer in the production of corrugated.

Patented Pleats: Corrugated packaging was initially produced by young girls who hand-fed sheets of strawboard through very simple bench-mounted machines that closely resembled those then in common use by laundries to pleat and crimp the edges of window curtains and the lace cuffs and collars of shirts and blouses. Samuel G. Cabell received a patent in 1866 for a laundry machine for fluting linen and laces.

Comprised essentially of a pair of hollow, fluted brass or bronze rolls that were heated by inserting hot rods or pokers and driven by hand crank, this machine was soon to be used in the production of the first corrugated.

Flexible Flutes: Corrugated paper material was patented in 1856 in England by Edward C. Healey and Edward E. Allen. The material patented was a form of fluted material for the sweatbands of hats. As a packaging material, it would be another 15 years before its introduction. On December 18, 1871, Albert L. Jones obtained U.S. patent 122,023, which envisions the use of unlined corrugated paper, formed with tubes and small boxes, for packaging small fragile articles such as glass vials and bottles. This packaging was resilient, lightweight, clean and inexpensive, and a market was promptly created for it. But it was dimensionally unstable and difficult to control ue to its extremely flexible, stretchy nature .